|

If you run a print shop or packaging line and need reliable folding at volume, choosing the right machine matters. This article compares the mini folder and the buckle folding machine across capacity, precision, paper types, and total cost of ownership — and gives a step-by-step decision process so you can pick the machine that fits your workflow. What each machine is best atMini folder

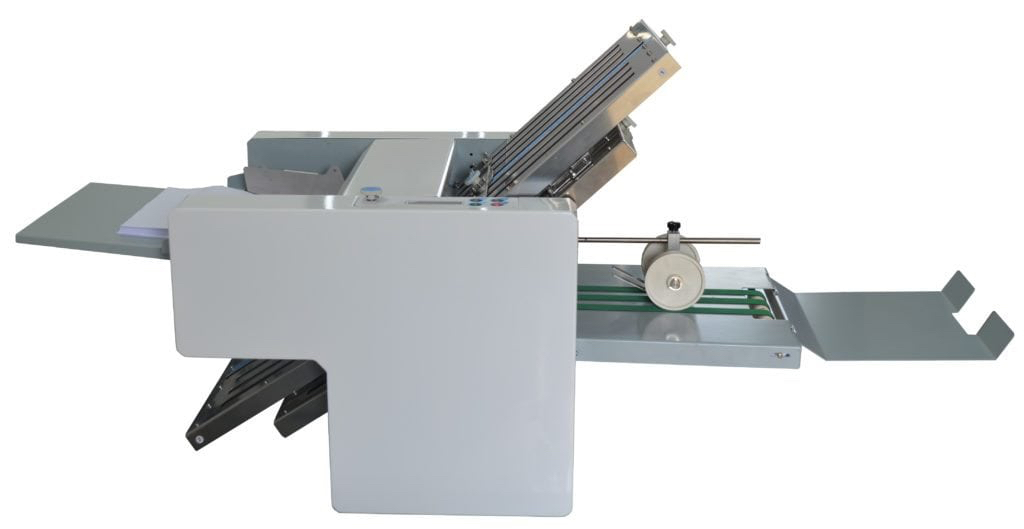

A mini folder is compact, fast to set up, and ideal for smaller runs, short folding patterns, and frequent job changes. It’s a strong choice when floor space is limited and you need efficient throughput for brochures, flyers, and small inserts. Buckle folding machine

A buckle folding machine (also called a buckle folder) uses a pair of rollers to create precise folds and is preferred for higher-volume work, heavier paper stocks, and jobs requiring consistent, repeatable folds. It handles a wide range of paper weights and more complex fold patterns than many mini folders. Quick comparison (at-a-glance)Throughput: Buckle folding machines ≥ Mini folders for sustained high-volume jobs. Setup & Changeover: Mini folders are generally quicker for short jobs and many small runs. Paper range: Buckle folding machines handle thicker stocks better. Precision: Buckle machines typically offer tighter, more repeatable fold accuracy. Footprint & Cost: Mini folders — lower initial cost and smaller footprint; Buckle machines — higher capital cost but better for continuous production.

How to decide — four practical stepsMeasure your typical job mix Average run length (e.g., 500, 5,000, or 50,000 copies) Frequency of job changes per shift

If most jobs are short runs with frequent changes, a mini folder often makes sense. If you run long, continuous batches, invest in a buckle folding machine.

Check paper specs and thickness Calculate total cost of ownership (TCO) Upfront price, expected uptime, maintenance intervals, spare parts, and operator labor.

A higher-capacity buckle folder may pay back through lower labor cost and less waste for large volumes.

Consider upgradeability and servicing Does the OEM provide local support and parts? Can the machine be upgraded (additional fold units, counters, feeders)?

Long-term serviceability is often more valuable than a slightly lower purchase price.

Sample customer scenario (illustrative)Acme Print handles a mix of 3,000–20,000-piece monthly runs and frequently prints coated brochures for local distributors. They originally used a compact mini folder for all jobs, but ran into misfeeds and wrinkling on 170–200 gsm coated stock. After switching to a medium-duty buckle folding machine, they reduced waste by 70% on heavy stocks and gained consistent fold precision for larger runs — the higher machine cost paid off within 18 months due to reduced rework. Practical on-the-floor tips (to reduce waste and downtime)Standardize job presets for common sizes to reduce setup time. Keep one trained operator per shift who knows the machine’s common fixes. Stock critical wear parts (belts, rollers, sensors) to avoid long downtime. Use test runs and a calibrated micrometer to check fold accuracy after setup.

Frequently asked questions (short)Q: Can a mini folder handle pharmaceutical inserts?

A: Yes for light to medium weight inserts and short runs. For thicker or large-volume pharmaceutical insert jobs, a buckle folder is safer. Q: How often do folding rollers need replacement?

A: That depends on usage and paper type — heavy or coated stocks wear rollers faster. Inspect them monthly in high-use operations. Q: Is automation worth it?

A: If your shop runs many similar large batches, automated feeders, pile lifts, and job memory pay back quickly by reducing labor and changeover time.

|